Wist je dat 9% van al het wereldwijde afval uit het ziekenhuis komt? En wist je dat 25-35% hiervan uit de operatiekamer komt? Het moge duidelijk zijn dat dit een groot probleem is waar veel duurzaamheidswinst te behalen is. Zo luidde onze uitdaging: “Hoe voorkomen we dat we zoveel restafval genereren in onze operatiekamer?” Afval verminderen kan op verschillende manieren, maar onze focus lag op het recyclen van afval. Tijdens dit project hebben wij een afvalanalyse uitgevoerd, een stappenplan in de vorm van een flowchart gemaakt en een ondersteunende e-learning gebouwd.

Afvalanalyse

Om de afvalanalyse uit te voeren, is er op de OK van het Medisch Spectrum Twente (MST) een week lang schoon plastic verzameld. Naderhand zijn enkele afvalzakken geopend en geanalyseerd om te ondervinden welke soorten plastic er veel worden gebruikt op de OK. Hiernaast gaf deze actie ons ook inzicht over wat de medewerkers vinden van afval scheiden en hun huidige kennis van dit onderwerp. Uit de afvalanalyse bleek dat doeken gemaakt van polypropyleen (PP) significant het meest voorkomende schone verpakkingsmateriaal zijn. Deze doeken worden op de OK gebruikt om instrumentensets in te pakken. Dit was een interessante uitkomst omdat PP een makkelijk te recyclen type plastic is en de doeken makkelijk onderscheiden kunnen worden van andere types plastic, zoals doorzichtig plastic verpakkingsmateriaal. Dit maakt het makkelijker voor de medewerkers, die aangeven dat het onderscheiden van wat nou allemaal onder plastic viel een uitdaging bleek te zijn.

Stappenplan

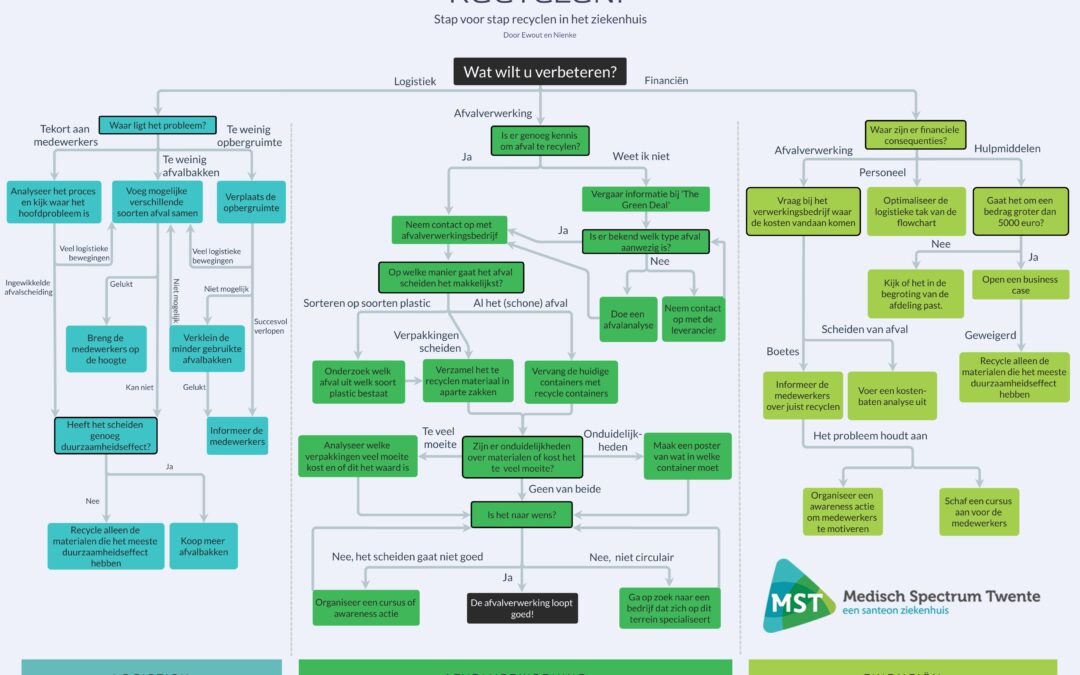

Dit is natuurlijk een mooie eerste stap, maar aan permanent recyclen zitten nog wel een paar haken en ogen. Zo zijn er bijvoorbeeld meer containers nodig en dat compliceert weer de logistiek. Hiernaast moet er een bestemming zijn voor het verzamelde afval waar het nuttig en duurzaam gebruikt wordt. Al met al zijn er veel dingen om aan te denken en omdat dit soms een beetje ingewikkeld kan worden hebben wij een flowchart gemaakt om het recycle proces overzichtelijk te maken. Deze flowchart is opgesplitst in een logistiektak, een afvalverwerkingstak en een financiëntak. Zo kan een ziekenhuisafdeling kijken op welk onderdeel zij vastlopen en worden zij daar gewezen op mogelijke oplossingen voor hun problemen. Om de stappen van de flowchart toe te lichten is er ook een e-learning gebouwd en deze e-learning zet de gebruikers ook zelf aan het nadenken over de materie.

Toekomst

De flowchart en e-learning worden momenteel geïmplementeerd op de OK van het MST, maar het uiteindelijke doel is om het te gebruiken in meer afdelingen en in meer ziekenhuizen. Door deze strategie op meer plaatsen toe te passen hopen we dat er meer kennis wordt uitgewisseld om het stappenplan nog meer te optimaliseren. Al met al hebben we een begin gemaakt aan het verduurzamen van het ziekenhuis en hopen we dat dit slechts een begin is van een grote oplossing.

– Ewout Ligtenberg en Nienke Buskens

Recent Comments